To drill and tap a hole on your workpiece you’re going to need to know your drill bit size and tap size for your hole. You can use this SAE drill and tap chart. You can also use this Metric drill and tap chart.

In this example you can see we want to use a 10-32NF threaded machine screw, we will need a 10-32NF tap, and to use this tap we need to drill a hole with a #21 drill bit, the closest fraction being 5/32″.

Generally speaking, you should mark the spot on your workpiece you are going to drill with a center punch. This will make sure you start drilling in the correct position and prevents slipping of the drill bit.

Drilling a hole:

Once you are ready to drill make sure you are drilling onto your workpiece straight down and not on an angle. Drilling on an angle can break your drill bit or ruin your end result. Clean your work area of chips and debris.

How to tap a hole:

Now you are ready to tap your hole, using a tap handle make sure your tap is secured inside and the tap is straight and perpendicular when entering the hole. Slowly turn the tap in a clockwise motion for a few turns while maintaining the tap in a straight position.

When you feel the tap cutting into the metal check that your tap is straight and perpendicular. Once you made a few turns go counter-clockwise half a turn after every full turn. This will remove the chips as you are creating new threads and will make it easier to tap your hole.

As you are tapping the hole you can use cutting oil when dealing with metals such as steel this will help make your tap last longer, remove chips more efficiently, and smoother and accurate threads on your workpiece.

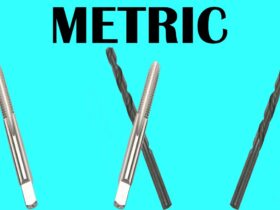

When tapping a hole you there are three types of taps to consider, a taper, plug, and bottom tap. The taper tap is used to start the thread in your hole but you should continue tapping with the plug and bottom if necessary.

A plug tap has more cutting threads with less of a taper than a taper tap, this can get the job done but if you have a blind hole you might want to finish off with a bottom tap. A bottom tap will bottom out on a hole when tapping, the only downside is you cant start tapping with a bottom tap since it has no taper.

Here is an image of a taper tap also known as a starting tap on the left, followed by a plug tap, then a bottom tap.

Now your hole should be tapped and perfect, run your bolt or machine screw through and enjoy the fruits of your labor.