What a coupling is

A shaft coupler is designed to transmit power from one shaft to another. This is in the form of rotational energy, from one shaft to another shaft. A shaft coupler will join the two shafts, allowing one rotating shaft to rotate a stationary shaft. You can find couplings in a lot of industrial applications such as a motor to an industrial air compressor, or even a motor to an industrial water pump to name a few.

When two shafts are connected with a coupling, misalignments have to be considered when choosing the appropriate coupling. There are three types of misalignments, excessive misalignment can damage bearings and other components. Couplings can be classified into three types mentioned below.

The three types of misalignments

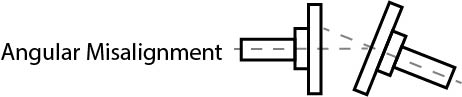

1. Angular misalignment

Angular misalignments can be summed as a difference in slope from one shaft to the other. A shaft has a rise and run, this is the slope of the shaft. When a shaft’s slope is different than the other shaft this is called angular misalignment.

2. Parallel misalignment

Parallel misalignment is also known as offset misalignment, which occurs when two shafts have a centreline that is parallel to each other. You can measure parallel misalignment by the distance between shaft centerlines.

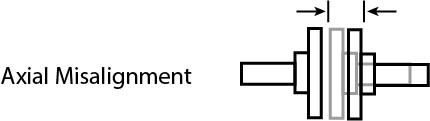

3. Axial misalignment

Axial misalignment is when the end of two shafts do not meet but have their centerlines in line. It is also known as end float or end play.

The three types of couplings

1. Rigid Coupling

Rigid couplings are the simplest of all coupling types. They are intended to connect two shafts that would be in a fixed position. There are some considerations when choosing a rigid coupling, angular misalignment is not acceptable with rigid couplings. The parallel misalignment shall be less than the bearing clearance. Heat is also another issue, it can cause axial misalignment while operating. So make sure the machine does not heat up when operating. Three basic types of rigid couplings are sleeve, flange, and ribbed couplings.

2. Flexible Coupling

Flexible Couplings are more forgiving when it comes to angular misalignment when compared to rigid couplings. However there is a maximum tolerance of misalignment allowed, excessive misalignment will reduce bearing and coupling life. There are two types of flexible couplings, mechanical and elastomeric.

a) Mechanical

Mechanical couplings allow misalignment through the sliding and rolling of their components. These types of couplings require a form of lubrication due to the constant movement of parts. Some examples of mechanical couplings are gear, chain, jaw and slider.

b) Elastomeric

Elastomeric couplings consist of two hubs and an elastic material joining the two hubs. Elastic materials such as natural rubber, synthetic rubber, and rubber-like plastics are used. This elastic material can withstand compressive or shear loads. Examples of elastomeric couplings are jaw couplings and donut couplings.

3. Universal Joint Coupling

A universal joint is also known as a U-joint is technically a flexible coupling but can transmit power at larger angles often as high as 30 to 40 degrees. The two simplest types of universal joints are the block and pin, bearing and cross. U-joints, do not accommodate for axial misalignment.